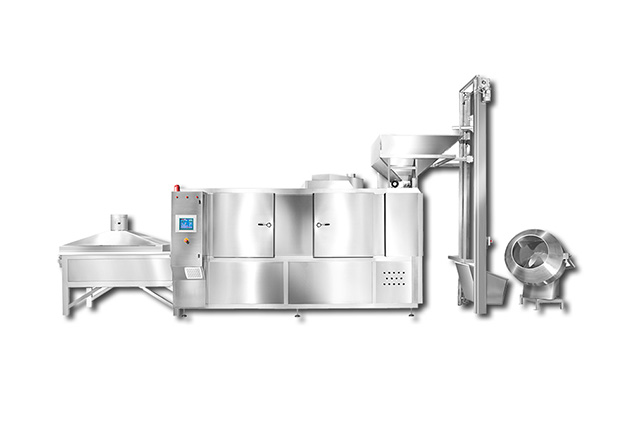

Ideal for roasting and drying of all kinds of Dry nuts, peanuts and seeds.

Our latest unique design provides only benefits and advantages. The Hot Air Tunnel Type Dry Roaster provides a uniform heat and air distribution throughout the whole roasting chamber, providing unique roasting color and final results such as taste, moisture and look. Designed for Roasting all kinds of dry nuts such as peanuts, almonds, pistachios, hazelnuts, cashews, macadamia nuts, sunflower and pumpkin seeds. The Hot Air Roaster has an increased air flow rate, allowing for higher rates of efficiency. Always keeping in mind that an oven needs to be cleaned as fast as possible, Belt Cleaning System, access doors around the Roasting chamber, slides, water drains, residual collection points, provide the operator with the full and fast as possible cleaning process of the Hot Air Roaster.

Uniform airflow increases product quality.

In our Hot Air Dry Nut Roaster you can find a unique airflow design to ensure uniform roasting across the levels of conveyor belts, producing uniform and stable roasting process.

Airflow is delivered both above and below the product layer, enhancing moisture removal and roasting characteristics while minimizing processing time.

Simple & Efficient operation.

One Roasting chamber, One Roasting zone, One burner, One heat exchanger. Direct drive of movement. Adjustable feeding equipment inside the roasting chamber, in order to deter the loss of hot air from the roasting chamber and as a result to gain energy and to achieve less consumption. Heat Exchanger, manufactured of stainless steel AISI 310S for high durability and dependability in high temperatures. Equipment that needs and help in 100% for the best possible and healthier roasting. Equipment that it is very difficult to find, in a Dry Nut Roaster. Our latest design was submitted in measurements with showing results 90%+ of thermal efficiency. The simplicity of the Hot Air Dry Nut Roaster ensures stable and uniform heat transfer and evenly spread according to the conveyor belts, eliminating the chances of fault. As a result, high efficient operation and precise control of roasting characteristics in addition to the lowest possible utility costs.

Fully adjustable, at any time for optimal performance.

The Hot Air Dry Nut Roaster is designed to cover all the specific heat treatment features of each product. The operator can adjust feed parameters, belt’s speed, roasting chamber’s temperature, amount of recirculation air, at any time to suit each dry nut individually and provide optimum performance. Mikropoulos Co can provide fully automatic roasting lines with a unique control panel. 12’’ Touch screen with PLC unit and built-in modem router, linked through Internet straight with our company for 24h service, available. Furthermore our control panel is programmable in order to set the parameters of your choice for each kind of dry nut.

Sanitary Design Available, unstoppable operation.

Our theory is that if it can be seen, it can be cleaned. Doors around the roasting chamber provide access to the entire interior. With external doors open, all areas of the roaster can be accessed for sanitation. Without any hide points, we minimize the risk of bacterial or fire growth.

Almost Fully assembled, minimum installation costs.

As the Hot Air Dry Nut Roaster shipped almost fully assembled , the installation time is the minimum possible and as a result the least expensive.

See the roasters catalogue in PDF

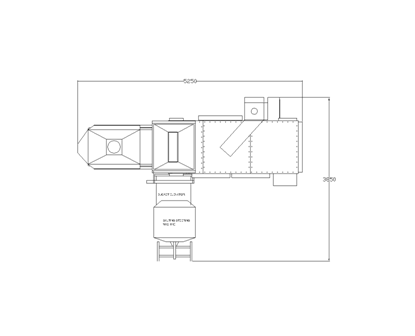

TA3-1200

TECHNICAL SPECS

| Type | Production | Power | Width | Length | Height | Weight |

| TA3 - 1200 | 500- 1200Kg/h | 23Kw | 4,3m | 15,2m | 4,2m | 7000kg |

Capacities per product

| Hazelnut | 1200Kg/h |

| Pistachio | 1000Kg/h |

| Almond | 1000Kg/h |

| Peanuts | 900Kg/h |

| Sunflower Seeds | 800Kg/h |

| Pumpkin Seeds | 800Kg/h |

| Peanut in Shell | 550Kg/h |

Thermal Power, Consumption of Fuels, Electrical Consumption

| Type of Fuel | Thermal Power | Consumption |

| Natural Gas | 420 – 470KW | 29 – 39 Nm3/h |

| LPG | 410 – 460KW | 25 – 36 Kg/h |

| Diesel | 420 – 470KW | 30 – 35,5 lt/h |

| Electrical Consumption | - | 20,5 Kw/h |

TA3-1000

TECHNICAL SPECS

| Type | Production | Power | Width | Length | Height | Weight |

| TA3 - 1000 | 450- 1000Kg/h | 21Kw | 4,3m | 12,5m | 4,2m | 6000kg |

Capacities per product

| Hazelnut | 1000Kg/h |

| Pistachio | 800Kg/h |

| Almond | 800Kg/h |

| Peanuts | 700Kg/h |

| Sunflower Seeds | 600Kg/h |

| Pumpkin Seeds | 600Kg/h |

| Peanut in Shell | 450Kg/h |

Thermal Power, Consumption of Fuels, Electrical Consumption

| Type of Fuel | Thermal Power | Consumption |

| Natural Gas | 400 – 450KW | 27 – 37 Nm3/h |

| LPG | 390 – 440KW | 25 – 34 Kg/h |

| Diesel | 400 – 450KW | 28 – 33,5 lt/h |

| Electrical Consumption | - | 18,5 Kw/h |

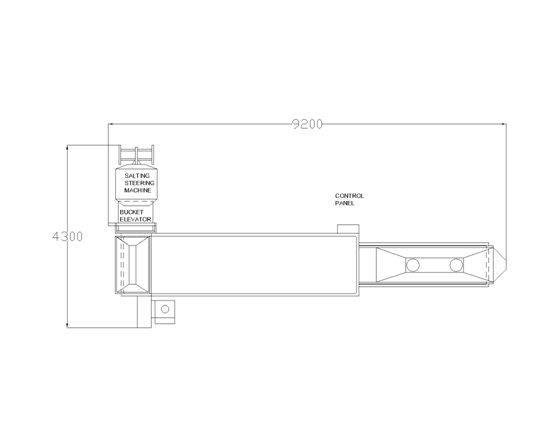

TA3-800

TECHNICAL SPECS

| Type | Production | Power | Width | Length | Height | Weight |

| TA3 - 800 | 350- 800Kg/h | 16,8Kw | 4,3m | 9,2m | 4,2m | 5400kg |

Capacities per product

| Hazelnut | 800Kg/h |

| Pistachio | 700Kg/h |

| Almond | 700Kg/h |

| Peanuts | 600Kg/h |

| Sunflower Seeds | 500Kg/h |

| Pumpkin Seeds | 500Kg/h |

| Peanut in Shell | 350Kg/h |

Thermal Power, Consumption of Fuels, Electrical Consumption

| Type of Fuel | Thermal Power | Consumption |

| Natural Gas | 280 – 300KW | 17 – 27 Nm3/h |

| LPG | 270 – 290KW | 15 – 24 Kg/h |

| Diesel | 290 – 300KW | 18 – 23,5 lt/h |

| Electrical Consumption | - | 13,5 Kw/h |

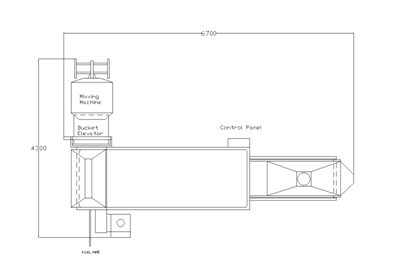

TA3-500

TECHNICAL SPECS

| Type | Production | Power | Width | Length | Height | Weight |

| TA3 - 500 | 250- 700Kg/h | 11Kw | 4,3m | 6,7m | 4,2m | 4200kg |

Capacities per product

| Hazelnut | 700Kg/h |

| Pistachio | 500Kg/h |

| Almond | 400Kg/h |

| Peanuts | 400Kg/h |

| Sunflower Seeds | 350Kg/h |

| Pumpkin Seeds | 300Kg/h |

| Peanut in Shell | 150Kg/h |

Thermal Power, Consumption of Fuels, Electrical Consumption

| Type of Fuel | Thermal Power | Consumption |

| Natural Gas | 190 – 215KW | 10 – 19 Nm3/h |

| LPG | 180 – 205KW | 9 – 16 Kg/h |

| Diesel | 190 – 215KW | 11 – 15,5 lt/h |

| Electrical Consumption | - | 7,9 Kw/h |

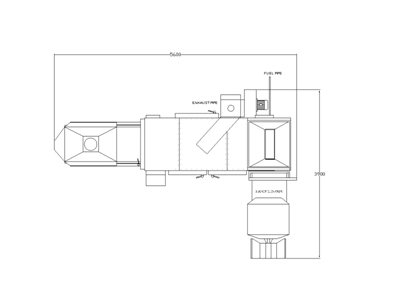

TA3-300

TECHNICAL SPECS

| Type | Production | Power | Width | Length | Height | Weight |

| TA3 - 300 | 100- 500Kg/h | 10Kw | 3,9m | 5,6m | 4,2m | 4200kg |

Capacities per product

| Hazelnut | 500Kg/h |

| Pistachio | 300Kg/h |

| Almond | 200Kg/h |

| Peanuts | 200Kg/h |

| Sunflower Seeds | 150Kg/h |

| Pumpkin Seeds | 150Kg/h |

| Peanut in Shell | 100Kg/h |

Thermal Power, Consumption of Fuels, Electrical Consumption

| Type of Fuel | Thermal Power | Consumption |

| Natural Gas | 135 – 155 KW | 8 – 12 Nm3/h |

| LPG | 125 – 145 KW | 6 – 10,5 Kg/h |

| Diesel | 135 – 155 KW | 7 – 11,5 lt/h |

| Electrical Consumption | - | 6,9 Kw/h |

TA2-200

TECHNICAL SPECS

| Type | Production | Power | Width | Length | Height | Weight |

| TA3 - 200 | 80- 300Kg/h | 8,5Kw | 3,9m | 5,6m | 3,5m | 2700kg |

Capacities per product

| Hazelnut | 400Kg/h |

| Pistachio | 200Kg/h |

| Almond | 150Kg/h |

| Peanuts | 150Kg/h |

| Sunflower Seeds | 80Kg/h |

| Pumpkin Seeds | 80Kg/h |

| Peanut in Shell | 50Kg/h |

Thermal Power, Consumption of Fuels, Electrical Consumption

| Type of Fuel | Thermal Power | Consumption |

| Natural Gas | 35 – 80 KW | 3 – 8,1 Nm3/h |

| LPG | 35 – 72 KW | 2,4 – 6,6 Kg/h |

| Diesel | 45 – 80 KW | 3,6 – 6,3 lt/h |

| Electrical Consumption | - | 5,9 Kw/h |

https://xmikropoulos.com/index.php/our-products/dry-nut-roasters/dry-nut-hot-air-tunnel-roaster#sigProId3f1b836a31